How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre production procedures represents a substantial improvement in quality assurance techniques. By using real-time, precise dimensions of Fibre sizes, this technology attends to the crucial demand for consistency in production standards. With its capacity to swiftly determine variances and punctual rehabilitative steps, the analyser not just enhances item reliability yet also adds to overall operational performance. As industries significantly prioritize high quality and conformity, understanding the complete influence of such developments comes to be important. What ramifications could this have for the future of Fibre production?

Relevance of Fibre Diameter Dimension

Precise measurement of Fibre Diameter is vital in the area of optical Fibre innovation, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission performance. Accuracy in gauging Fibre Diameter ensures that the optical residential or commercial properties are maintained within specified resistances, which is crucial for ideal signal stability.

Variations in Fibre Diameter can result in increased losses as a result of spreading and modal dispersion, impacting the quality of information transmission. In high-speed communication systems, such discrepancies can result in substantial deterioration of signal quality, leading to information errors and reduced efficiency. Regular Fibre Diameter is necessary for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily count on accurate Diameter measurements to make certain compliance with market criteria. By carrying out robust measurement strategies, makers can enhance product integrity, reduce waste, and boost general system efficiency. Thus, the value of Fibre Diameter dimension can not be overstated, as it functions as a keystone in the improvement of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Functions

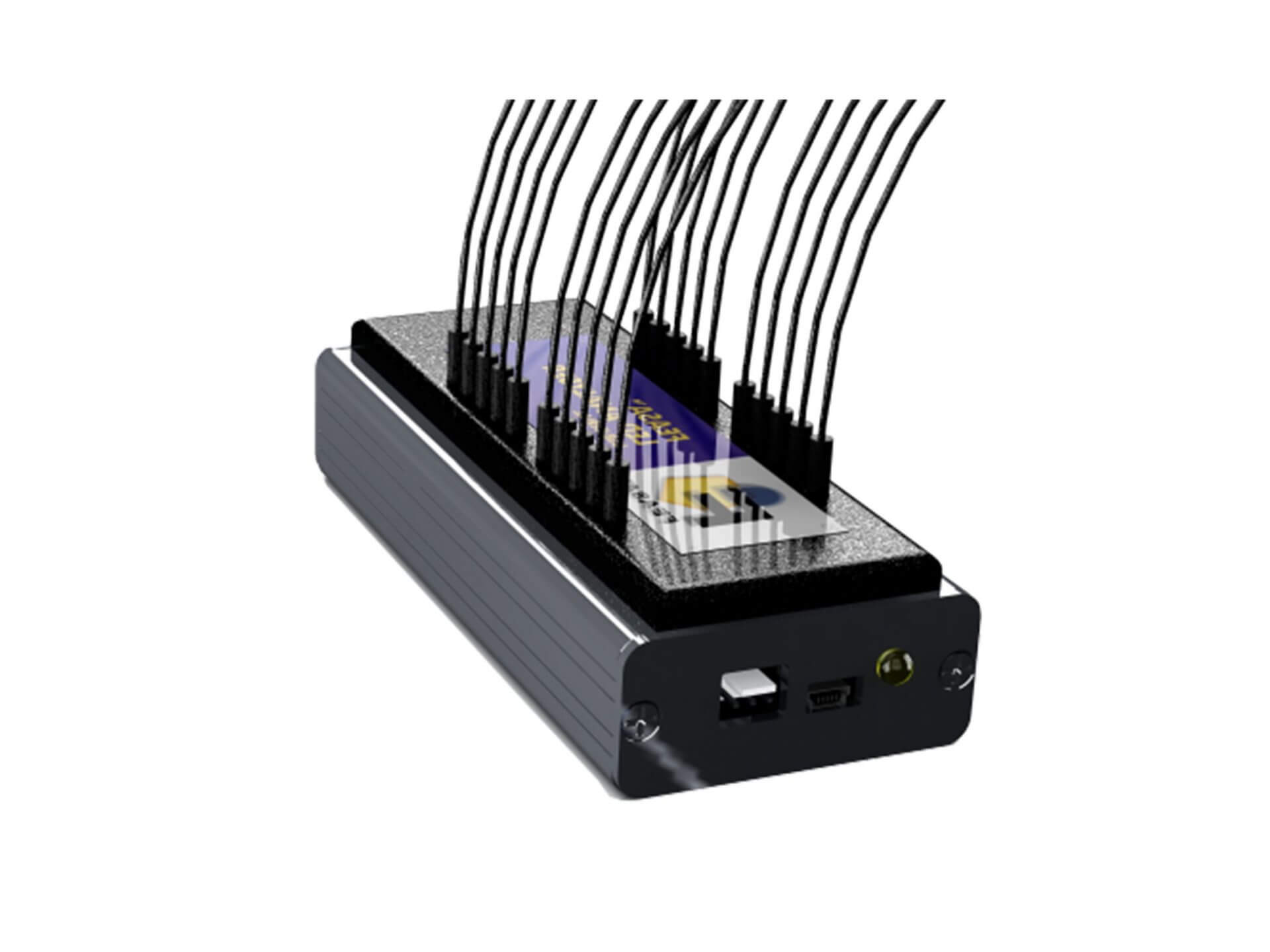

The reliable measurement of Fibre Diameter relies upon advanced logical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced picture handling formulas to accurately evaluate the Diameter of fibers as they are generated

Initially, a laser beam of light is guided at the relocating Fibre, creating a cross-sectional shadow. The analyser catches this darkness making use of high-resolution cameras placed tactically along the manufacturing line. The captured images are then processed in real-time to figure out the Fibre's Diameter with exceptional accuracy.

The system utilizes sophisticated algorithms that represent different aspects, consisting of variants in light strength and ecological problems, to improve measurement dependability. It can find minute adjustments in Diameter, such as changes that may happen throughout the manufacturing process.

Additionally, the analyser is qualified of managing several fibres simultaneously, increasing throughput without endangering precision. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a crucial duty in preserving strict quality control criteria, making sure that the final product fulfills market specifications and consumer demands.

Benefits of Real-Time Surveillance

While standard methods of checking Fibre Diameter commonly involve taxing post-production checks, real-time tracking considerably boosts the effectiveness and quality of optical Fibre production. optical fibre diameter analyser. This positive approach enables manufacturers to recognize discrepancies in Fibre Diameter as they happen, as opposed to waiting up until manufacturing is total to assess high quality

By continuously determining the Diameter during manufacturing, manufacturers can make sure that the fibres satisfy rigorous specs, bring about decreased irregularity and improved consistency. Real-time surveillance also allows prompt corrective actions to be taken, reducing waste and protecting against defective fibres from getting in the supply chain.

Furthermore, this innovation promotes enhanced data collection and analysis, supplying understandings into production patterns and prospective locations for renovation. Such data-driven decision-making empowers producers to enhance procedures and keep high criteria of quality assurance.

On top of that, real-time tracking promotes a society of continual renovation within the manufacturing setting. Workers are more engaged when they can see the influence of their work in real-time, resulting in increased liability and a dedication to excellence. Overall, the application of real-time surveillance systems in optical Fibre production converts to exceptional product high quality and enhanced customer complete satisfaction.

Influence On Production Effectiveness

Applying optical Fibre Diameter analysers dramatically improves production effectiveness by improving the production procedure. These gadgets promote continuous tracking of Fibre Diameter, enabling makers to detect discrepancies in real-time. By recognizing incongruities quickly, assembly line can be changed rapidly, reducing downtime and lowering the possibility of generating malfunctioning items.

Furthermore, the combination of these analysers into the production process enables much better resource allocation. With exact Diameter measurements, operators can maximize material usage, making certain that sources are not lost on flawed fibres. This accuracy additionally adds to less junk and revamp, eventually decreasing manufacturing additional resources expenses.

The automation supplied by optical Fibre Diameter analysers reduces dependence on hands-on evaluations, which are vulnerable and commonly lengthy to human mistake. Therefore, workers can concentrate on more calculated jobs, improving total efficiency.

Additionally, the data generated from these analysers can educate process renovations and assist in much better decision-making. By assessing patterns in Fibre Diameter variants, makers can implement aggressive steps to improve production strategies and maintain constant quality. In recap, optical Fibre Diameter analysers play an important duty in improving production effectiveness, bring about higher high quality result and raised success.

Study and Success Stories

Throughout various industries, situation why not look here researches highlight the transformative influence of optical Fibre Diameter analysers on manufacturing processes. One prominent instance is a leading telecoms business that faced difficulties with inconsistent Fibre diameters, leading to boosted being rejected prices. By integrating an optical Fibre Diameter analyser, the firm accomplished real-time surveillance of Fibre dimensions, leading to a 30% decrease in defects and significant cost savings.

In addition, a study institution concentrating on advanced materials utilized optical Fibre Diameter analysers to fine-tune their experimental procedures. The analyser's capacity to offer detailed understandings into Fibre consistency allowed the development of ingenious products with enhanced efficiency qualities.

These success try these out tales highlight the essential function of optical Fibre Diameter analysers in improving quality control, improving production effectiveness, and driving technology across varied sectors.

Verdict

In conclusion, the Optical Fibre Diameter Analyser plays a pivotal role in improving high quality control within Fibre production. As demonstrated with various instance researches, the analyser shows vital for accomplishing remarkable product high quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers allowed for stringent high quality control, making sure that the generated fibres satisfied exacting industry criteria.In verdict, the Optical Fibre Diameter Analyser plays a critical function in improving quality control within Fibre production.